In the field of laboratory testing, 200Hz is often the go-to frequency for most applications, delivering reliable and precise results in a wide variety of scenarios. It’s a tried-and-true standard that meets the needs of many industries. But what happens when your testing requirements go beyond the typical? That’s where vibration testers with 300Hz capability come into play, offering an exciting opportunity to expand your testing range and unlock new insights.

However, as we explore the potential of higher frequencies, it’s equally important to focus on the critical role of minimum frequencies, such as 10Hz. Low-frequency testing is essential in applications where certain electromagnetic machines struggle to perform optimally at these ranges. Ensuring your vibration tester can handle these low frequencies is vital for comprehensive and effective testing.

By understanding the strengths of both the high and low ends of the frequency spectrum, you can make more informed decisions and ensure your laboratory is equipped to tackle even the most demanding testing scenarios. Let’s dive into the benefits of 300Hz vibration testers and how to make the most of their capabilities.

How vibration testers work: a technical perspective

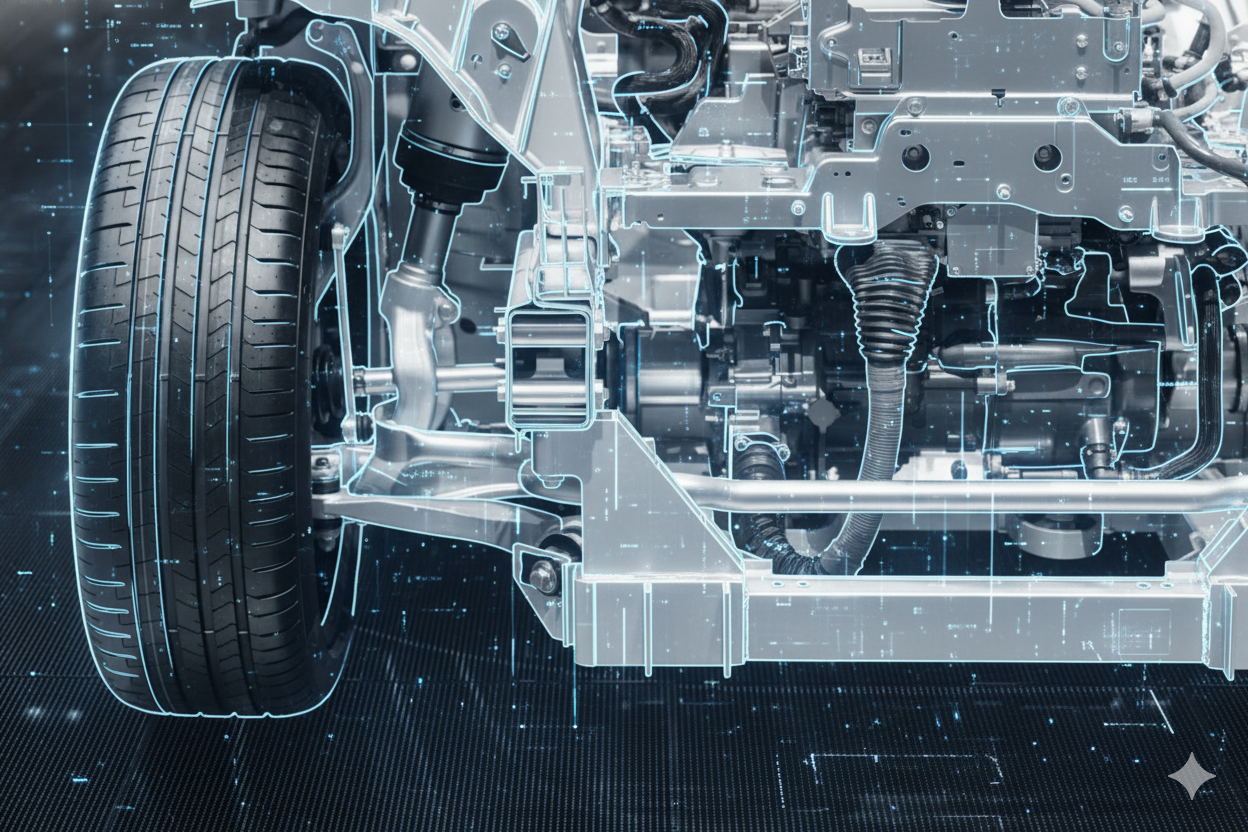

A hydraulic vibration testing system is composed of several critical components that work in unison to deliver precise and controlled vibrations. These systems are particularly suited for heavy-duty applications and testing scenarios requiring high force and robust performance. Here’s a breakdown of the key components:

- Shaker Table or Platform:

The surface where the test specimen is securely mounted. Hydraulic systems excel at supporting large, heavy specimens without compromising vibration accuracy.Hydraulic Actuator:

The core of the system, the hydraulic actuator, generates the required vibrations by converting hydraulic energy into mechanical motion. Hydraulic shakers are designed to provide consistent performance across a wide range of frequencies, including up to 300Hz, offering excellent adaptability for diverse testing needs.

Thanks to their precise positioning capabilities, hydraulic actuators perform exceptionally well at low frequencies, such as 10Hz. Their accuracy ensures that the hydraulic system consistently reaches the desired position, enabling reliable and repeatable results. This precision contrasts with electromagnetic systems, which often struggle to maintain positioning at low frequencies, resulting in reduced reliability for these specific applications.

By leveraging the strengths of hydraulic actuators, laboratories can ensure greater accuracy and reliability in scenarios where low-frequency testing is critical.

Vibration Controller:

The controller is a critical element that ensures the precision of the testing process. It allows fine-tuning of key parameters such as frequency, amplitude, and waveforms. Modern vibration controllers integrate advanced algorithms to provide stable, repeatable, and customizable vibration profiles, making them indispensable for high-accuracy testing scenarios.